Injection Facilities

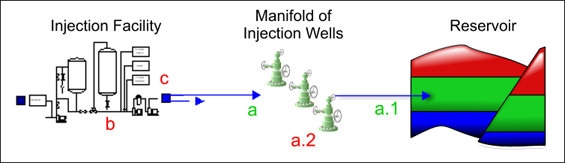

Injection facilities inject fluids into the subsurface. They receive water or gas from the field or from an external source, and send it to a group of injectors or route it downstream.

The following kinds of injection facilities exist:

.png) Water Injection Facilities

Water Injection Facilities.png) Gas Injection Facilities

Gas Injection Facilities

Apart from the usual inputs for all facility types, injection facilities are characterized by Injection Capacity and Injection Supply (external source of fluid), both of them defined in the facility General Tab (Facility).

All injection facilities have necessarily a manifold group of injection wells associated to them; no other kind of well can be included in the group that injectors of the corresponding fluid. The group is automatically created along with the facility and is only deleted if the facility is deleted too. See further in Manifold Groups.

How Injection Works

There are three parameters that determine the rate at which injection facilities process fluids:

- The amount requested by the group of injection wells associated to the facility. In the case of

.png) water injection facilities, this is the amount requested for reservoir Voidage Replacement (a.1), as defined under Water Injection Options; it is distributed among all injection wells in that reservoir proportionally to the wells' performance (a.2) defined in each Well Performance Tab.

water injection facilities, this is the amount requested for reservoir Voidage Replacement (a.1), as defined under Water Injection Options; it is distributed among all injection wells in that reservoir proportionally to the wells' performance (a.2) defined in each Well Performance Tab. - The facility's max injection capacity defined in the facility General Tab (Facility).

- The out connector capacity defined in the Capacity Sub-Tab.

See further under How is water and gas injection constrained?

By default, injection facilities are provided with a disposal out connection that will account for the excess water/gas, thus preventing any excess in injection fluid from choking the routing system. Use the Delete / Add final connection option in the Surface Layout if you wish to delete this disposal connection and allow the system to choke when in excess of injection fluid.

Injection facilities cannot have out connectors for components of the injection fluid, i.e. cannot be used as separators of the injection fluid.